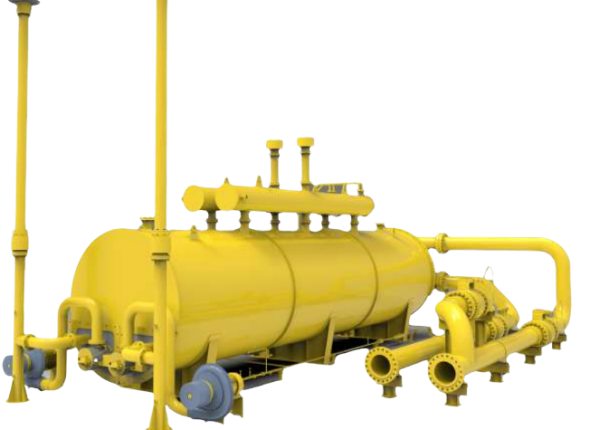

Indirect water bath heaters are meticulously engineered systems designed for effective gas heating without high-pressure containment. These systems operate by circulating gas through a coil submerged in a heated water bath, powered by an external burner. This indirect heating method ensures uniform temperature management and minimizes the risk of hotspots and carbon buildup.

The key features include:

Leave us a Message

Leave us a Message