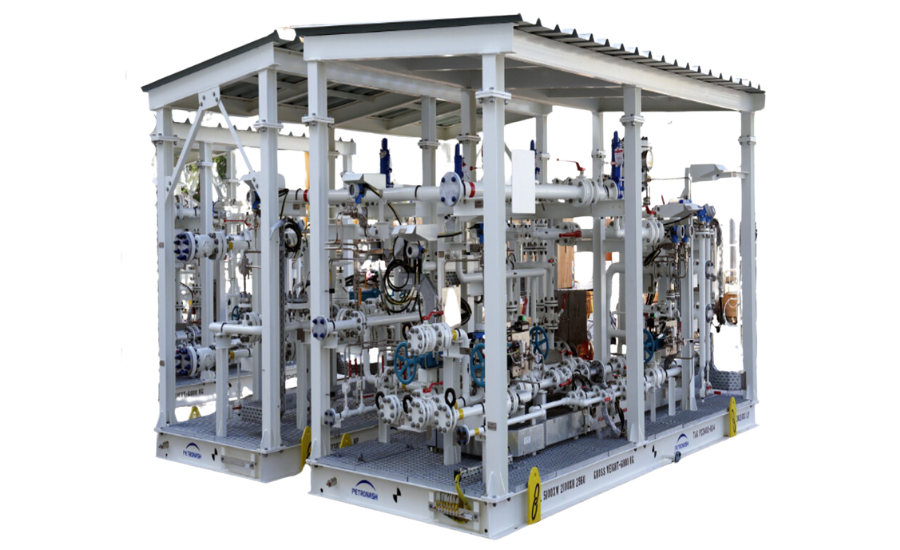

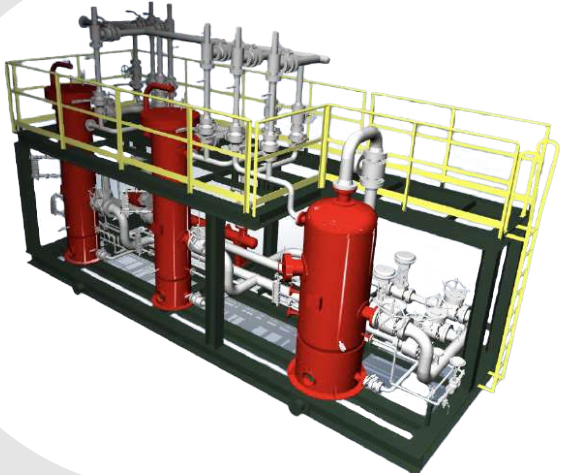

The Fuel Gas Conditioning system is designed to optimize the treatment of fuel gas by removing solids and liquids, ensuring the gas meets critical process conditions such as temperature and pressure. This conditioning is essential for meeting emission standards and extending the lifespan of downstream equipment.

Fuel gas conditioning is necessary to prevent damage to the internal components of engines and turbines. This process involves pre-treating gas from sources such as GDUs or sales gas pipelines to remove impurities that could adversely affect engine performance.

The key components of a fuel gas conditioning system include:

The primary benefits of a fuel gas conditioning system include:

Leave us a Message

Leave us a Message