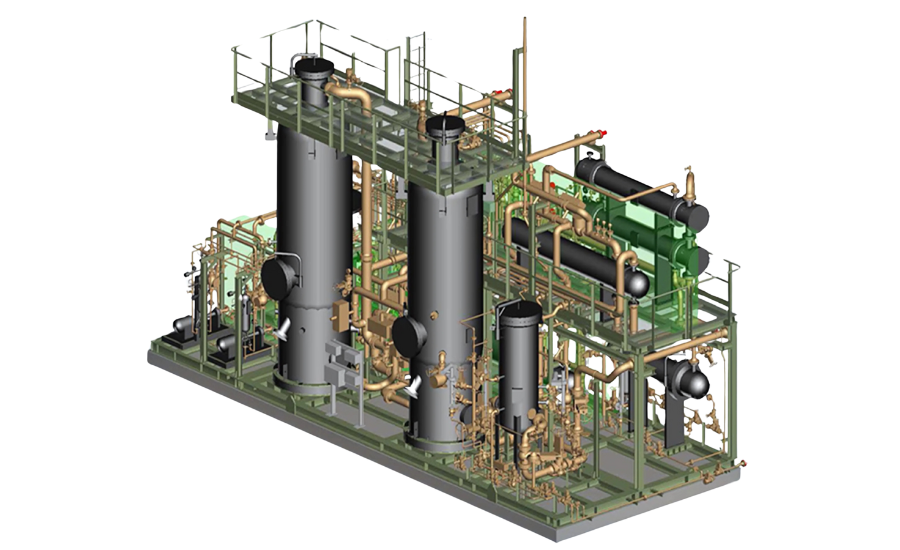

Our state-of-the-art molecular sieve dehydration units are designed specifically for the natural gas industry. These units are engineered to achieve ultra-low water dew points, making them essential for cryogenic processing and ensuring the integrity and efficiency of downstream operations.

Petronash is at the forefront of innovation in the field of corrosion inhibition measurement. Our LabBox offers a faster, more rugged, and high-performance method of measuring residual corrosion inhibitor levels.

The LabBox uses fluorescence emission analysis to measure corrosive material in the process line and others.

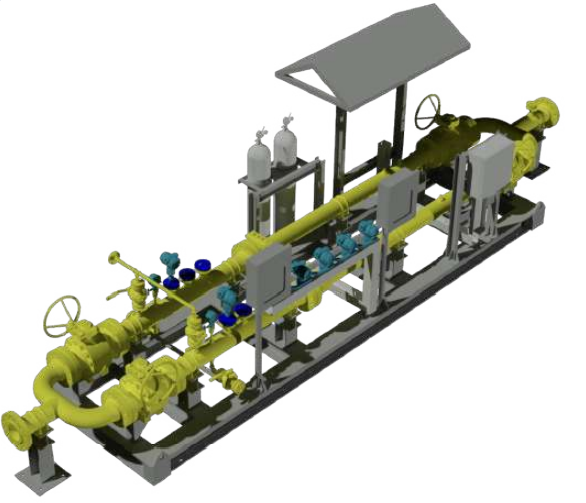

Chemical dosing infrastructure.

Our LabBox solution is a quicker, more accurate, and cost-effective method of monitoring corrosion levels, providing operators with unparalleled insights into the performance of their assets.

Leave us a Message

Leave us a Message