Petronash specializes in Chemical Injection Systems (CIS) that ensure optimal production integrity, flow assurance, and operational efficiency. We do not just manufacture skids; we provide comprehensive solutions by taking ownership of the entire process—form, determining chemical selection and dosing rates to ensure the system operates seamlessly within your production environment.

Petronash excels in the design, engineering, and manufacturing of Chemical Injection Systems customized to meet customer specifications and requirements for a wide range of applications including corrosion inhibition, scale prevention, hydrate management, or other flow assurance needs across the energy industry.

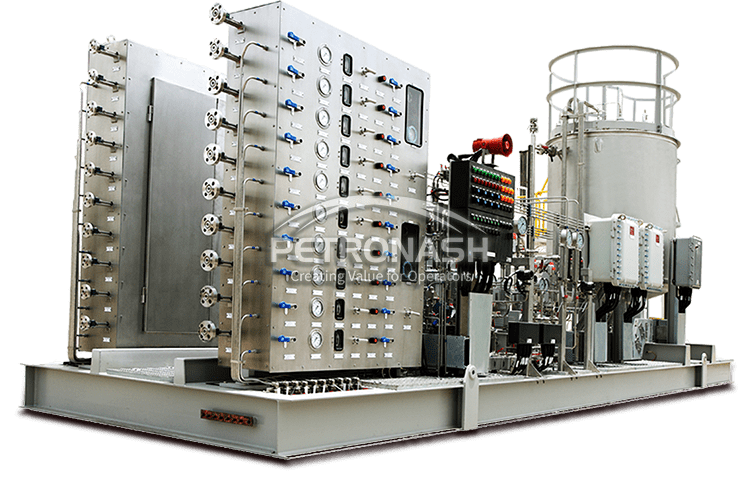

The Conventional Chemical Injection Package comes with a basic configuration that includes a chemical storage tank, pumps, valves and instrumentation, associated piping, and electrical controls.

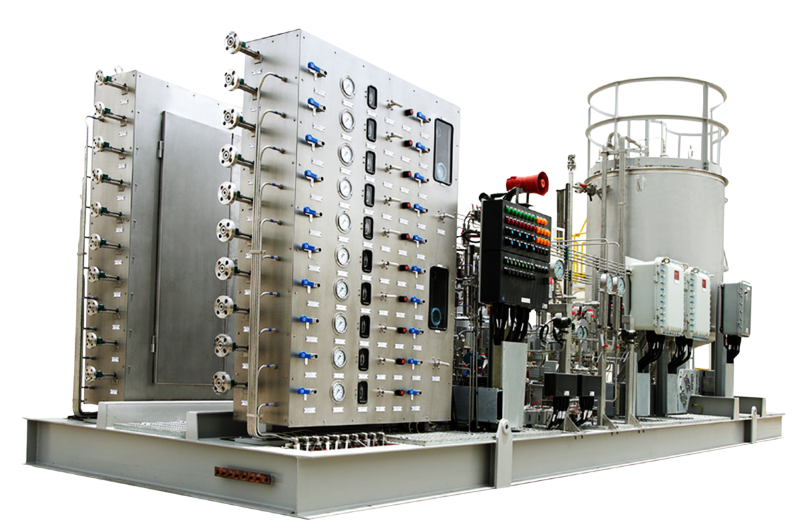

The Multi-Point Chemical Injection Package serves the purpose of injecting the same chemical at different injection points, at different flow rates and injection pressures.

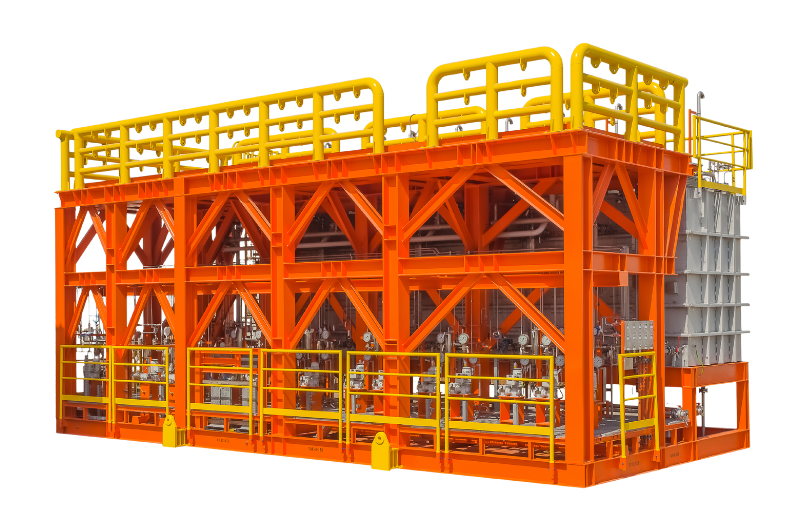

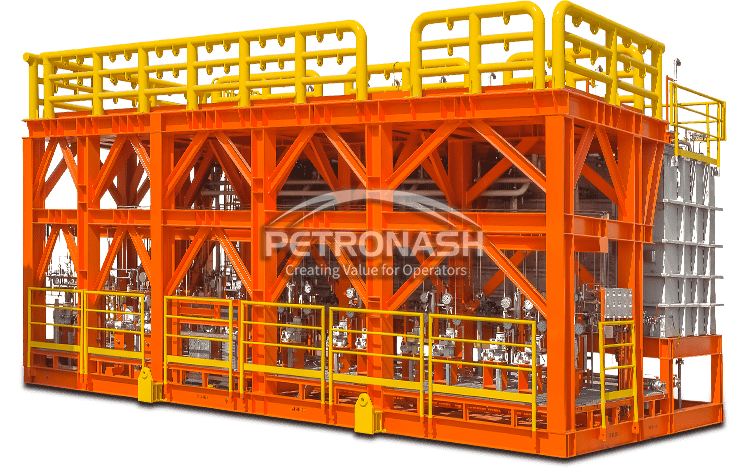

Multi Compartmental Tank Package is a type of chemical injection package which is most suitable at offshore platforms where there are severe space constraints and a need for injecting different chemicals at the same location.

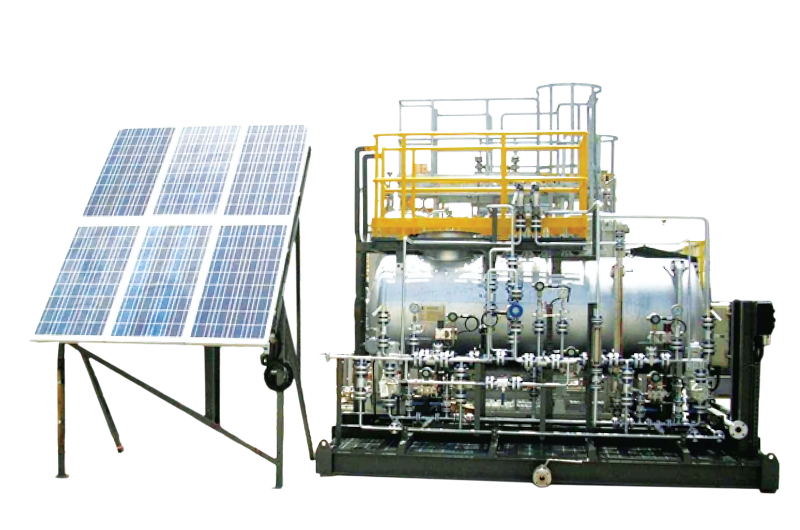

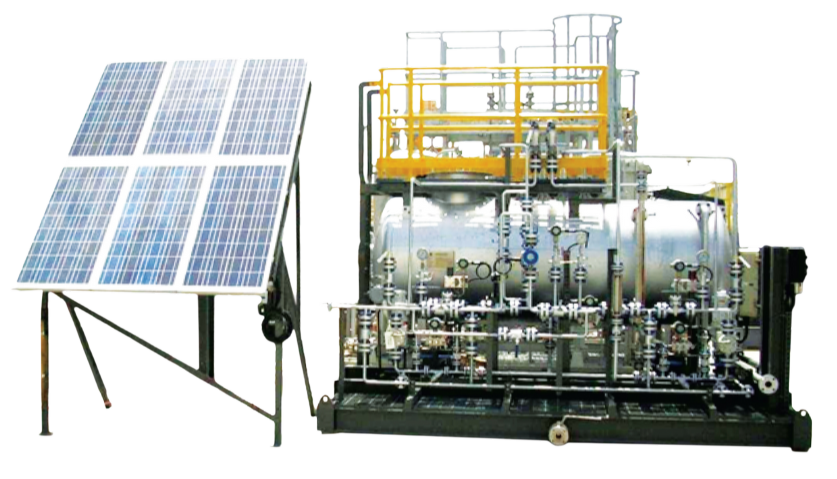

These types of chemical injection packages are normally used in remote areas where a conventional source of electrical energy is not available. These packages tap the solar energy and convert it into electrical energy to drive the pump.

These packages are designed to operate in sub-zero environments. These injection systems are supplied with electric / steam tracing system and insulation to prevent the chemical from freezing and vapour condensation.

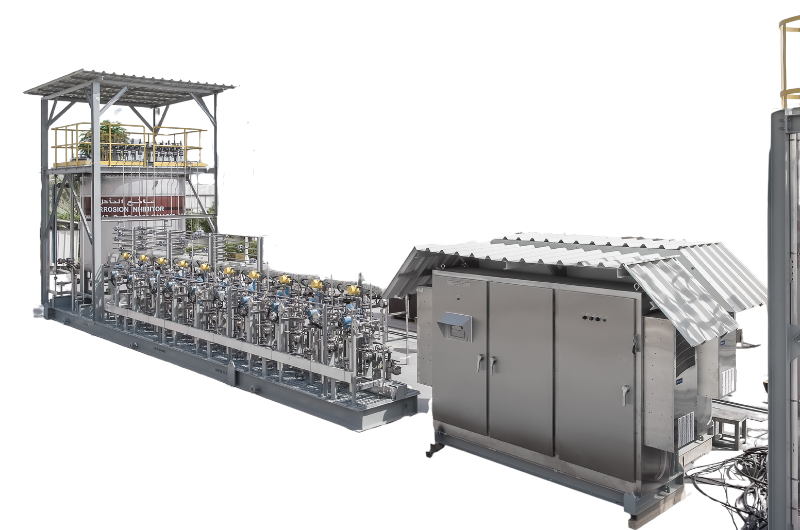

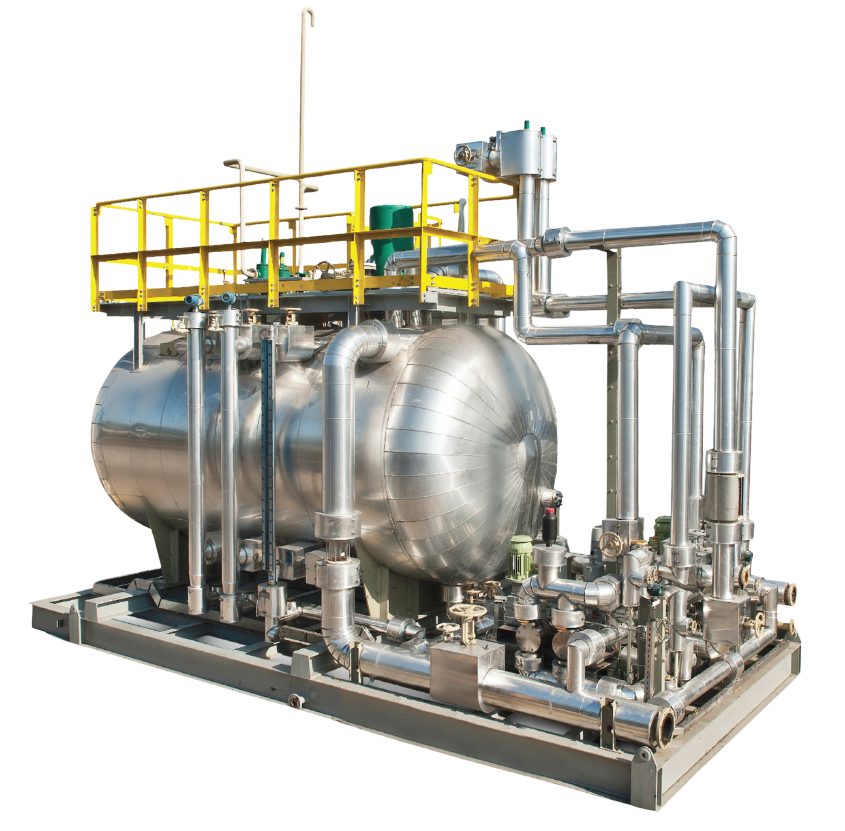

Drag reducing agents (DRA), also known as flow improvers are injected into Cross Country Pipeline/flowlines to reduce turbulent flow. Due to its chemical properties of high viscosity and heavy molecular weight nature, it is one of the most difficult chemicals to handle.

0.12 LPH / 21,000 LPH

Atmospheric / 690 Barg

1 / 2000 cP

1 / 190m3

10mm / 60mm

21,800mm (L) x 5,000mm (W) x 6,890mm (H)

9,880mm (H)

Leave us a Message

Leave us a Message