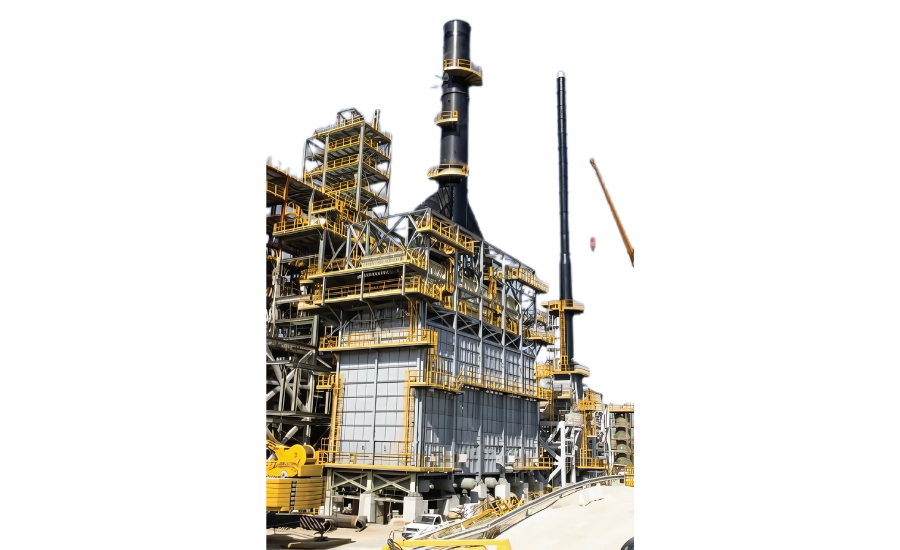

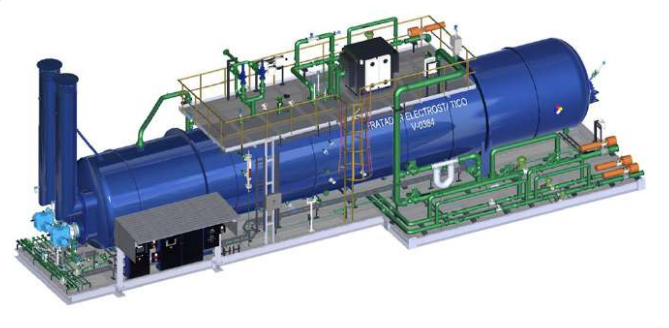

Fired heaters are specifically engineered for high efficiency and effective oil heating. All fired heaters are designed in compliance with API 560 & ISO13705 standards, showcasing a strong track record in the oil and gas industry.

Our heaters are available in cylindrical, box, and cabin configurations to meet various operational needs. The most common option is the vertical cylindrical heater, but other options include:

Key components of a fired heater include:

Leave us a Message

Leave us a Message